- Blog

- Geo Scheduling

- Intelligent Optimization: The Future of Operational Planning

Intelligent optimization is quickly becoming the backbone of modern operational planning, especially for organizations managing complex, fast-moving workflows. By combining machine learning with rules-based engines, intelligent optimization helps teams automate decisions, streamline processes, and adapt instantly when conditions change. This next-generation approach replaces manual guesswork with data-driven clarity, allowing planners to forecast demand, allocate resources, and resolve constraints in real time. As logistics, field service, and delivery-based operations grow more dynamic, intelligent optimization provides the agility and accuracy they need to stay ahead.

What Is Intelligent Optimization?

Intelligent optimization is the fusion of machine learning, decision intelligence, and rules-based logic to improve operational planning at scale. Rather than relying on static schedules or manual adjustments, it continuously evaluates real-time inputs and recommends the best possible actions. This includes allocating resources, prioritizing tasks, sequencing routes, and predicting potential disruptions before they happen. The goal is to produce decisions that are smarter, faster, and more efficient than traditional planning methods. As a result, teams gain a deeper understanding of their workflows and unlock immediate improvements in accuracy, speed, and cost savings.

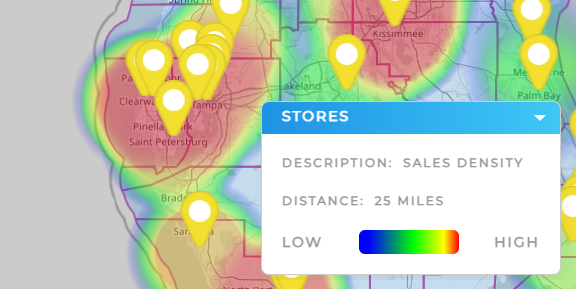

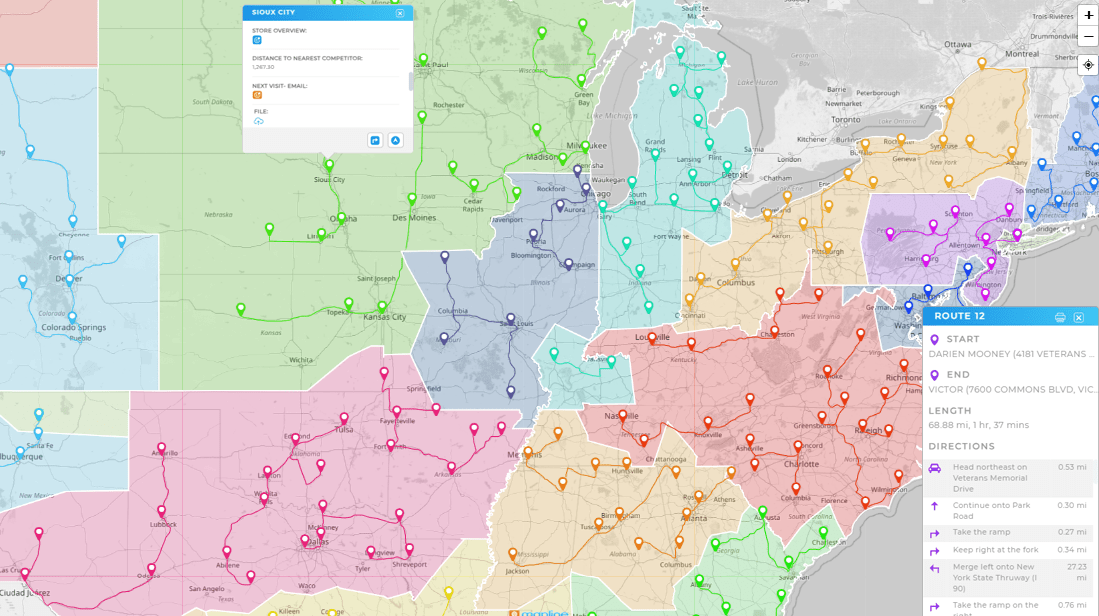

Pro Tip: Combine intelligent optimization with geographic insights to build even stronger operational plans. When machine learning, business rules, and map-based data work together, every decision becomes location-aware — improving accuracy, performance, and response time.

A Hybrid Approach to Decision-Making

At its core, intelligent optimization blends data-driven predictions with rule-based constraints to produce feasible, real-world outcomes. Machine learning models analyze historical patterns and anticipate future behavior, while a rules engine ensures recommendations comply with business requirements, capacity limits, and operational restrictions. This hybrid approach gives companies the best of both worlds: adaptive intelligence plus strict adherence to real-world conditions.

Always Learning, Always Improving

Unlike static planning tools, intelligent optimization evolves with each new data point. Machine learning models continuously refine their predictions based on outcomes, feedback, and environmental changes. This ensures recommendations stay aligned with real-time realities, even when demand spikes unexpectedly or timelines shift. As these systems learn, they deliver increasingly accurate insights that empower teams to make proactive decisions.

Built for Scale and Complexity

Traditional planning systems often break down under large datasets or scenarios with interdependent variables. Intelligent optimization is built specifically for these environments, processing thousands of inputs simultaneously and resolving conflicts automatically. Whether you’re managing a nationwide fleet or a growing service operation, it scales effortlessly while maintaining precision. This makes it especially valuable for organizations with multi-level workflows and high constraint density.

How Intelligent Optimization Transforms Logistics and Field Operations

Logistics and field operations rely heavily on timing, coordination, and resource availability — areas where intelligent optimization delivers a measurable performance boost. By automating core decision-making processes, teams reduce delays, minimize manual errors, and respond faster to operational shifts. Machine learning models provide predictive insight, while rules engines ensure decisions remain aligned with business strategy and compliance needs. Together, they create a powerful ecosystem for high-efficiency planning.

Real-Time Route and Schedule Adjustments

Intelligent optimization recalculates routes and schedules instantly when technicians run late, new jobs are added, or traffic conditions change. Machine learning models identify the fastest resolutions, while business rules determine which technician is qualified, available, or within the right territory. This prevents backlogs and ensures customers receive timely service, even in unpredictable conditions.

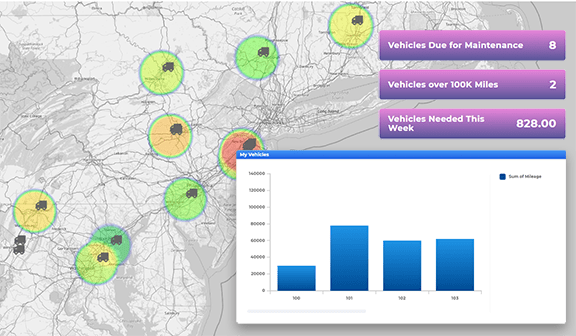

Predictive Demand Forecasting

Machine learning evaluates historical patterns to anticipate upcoming demand surges or dips. This allows planners to staff appropriately, assign workloads efficiently, and prepare resources ahead of time. By pairing forecasts with strict operational rules, teams avoid overcommitting resources or underestimating capacity. The result is smoother throughput and fewer last-minute fire drills.

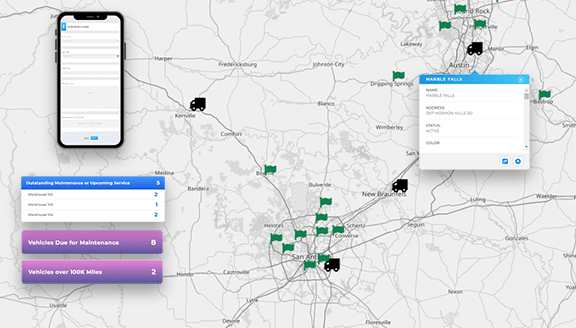

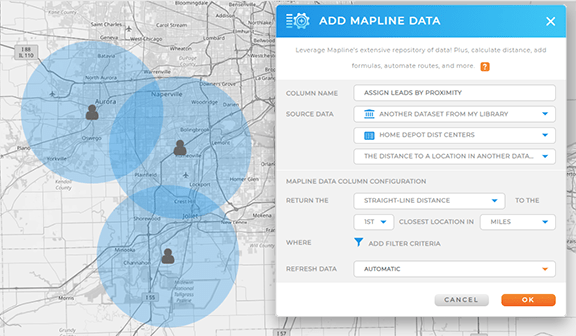

Automated Resource Allocation

Rules-based engines ensure each resource — whether a vehicle, a technician, or a delivery asset — is assigned in the most efficient and compliant way. The system accounts for working hours, skill sets, delivery windows, and route constraints to produce an optimized plan automatically. This eliminates manual bottlenecks and improves productivity without sacrificing quality or compliance.

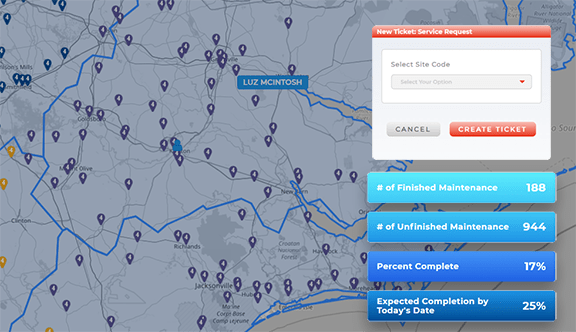

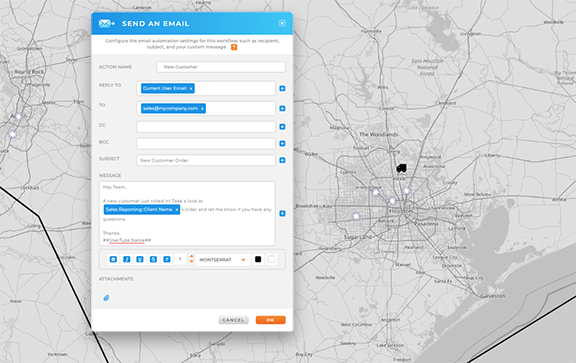

Improved Exception Handling

Operational disruptions happen constantly, especially in fields like logistics and home service. Intelligent optimization detects exceptions early and triggers automated responses that minimize delays. By combining predictive analytics with rule-based actions, teams resolve issues faster and reduce the cascading impact of missed appointments or delayed deliveries. This leads to stronger performance metrics and more consistent customer experiences.

Decision Intelligence as a Competitive Advantage

Decision intelligence takes the power of intelligent optimization a step further by connecting insights, predictions, and recommendations into a cohesive decision-making framework. It helps teams understand not only what to do, but why a certain action is the best choice. With clear reasoning behind each recommendation, leaders can trust the system’s output and make informed, strategic decisions that align with long-term goals.

Transparent Recommendations

Decision intelligence provides visibility into the logic behind each optimized recommendation. Teams can see which constraints were applied, which bottlenecks were resolved, and which alternatives were evaluated. This transparency builds trust and allows planners to validate outcomes rather than relying solely on instinct.

Faster Alignment Across Teams

When recommendations are backed by clear reasoning, alignment happens faster. Sales, operations, and dispatch all understand the rationale behind scheduling changes or resource reallocations. This reduces friction, prevents siloed decision-making, and ensures everyone is working toward the same operational goals. As a result, teams move more efficiently and with greater confidence.

More Accurate Long-Term Strategy

Decision intelligence aggregates insights from every operational cycle, helping leaders identify long-term trends and areas for improvement. Instead of reacting to problems, companies build strategic plans that minimize risk and maximize throughput. Over time, this creates a competitive edge rooted in smarter, more informed decision-making.

It’s the combination of machine learning, rules engines, and decision intelligence to automate and improve operational planning.

Traditional systems rely on static rules, while intelligent optimization adapts in real time and predicts future scenarios.

Logistics, field service, delivery operations, and any workflow with dynamic, high-volume scheduling needs.

No — modern platforms are built for business users and include no-code configuration options.

Yes — machine learning models analyze historical data to predict workload, staffing needs, and resource requirements.