- Blog

- Geo Routing

- The Cost of Bad Routing: How Hidden Inefficiencies Drain Profit

Most organizations feel the pain of bad routing long before they recognize the cause. Missed delivery windows, overloaded drivers, wasted miles, and overtime costs all stem from one core issue: inefficient route planning. While spreadsheets, static maps, and manual assignments may work at small scale, they break instantly as operations grow. The routing problem becomes exponential—every new stop, driver, and constraint increases the chance of costly inefficiencies that drain profit every single day.

Modern businesses need more than a simple route planner. They need vehicle routing optimization that accounts for real-world variables: traffic, service windows, capacity limits, multiple depots, and the nonstop flow of new customer requests. Without it, teams overspend on fuel, fall behind schedule, and struggle to meet service-level expectations. Bad routing isn’t just an annoyance—it’s one of the most expensive hidden problems in field operations and logistics.

Why Poor Routing Decisions Cost More Than You Think

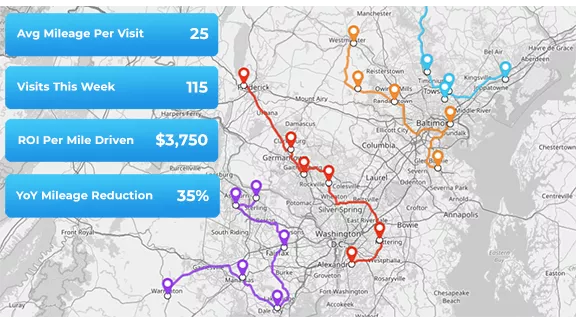

Every inefficient route adds incremental cost—longer drive times, unnecessary miles, and preventable labor hours. When multiplied across dozens of drivers and hundreds of stops, those small inefficiencies turn into massive financial leakage. Bad routing also affects team morale, leading to burnout when workloads are uneven or unrealistic. Customers feel the impact too, experiencing delayed deliveries, unpredictable service windows, and missed appointments.

And when routing decisions are made manually, even the most experienced dispatcher can’t account for the thousands of possible route permutations required to achieve truly optimal routing. Without a vehicle routing system that adapts automatically, companies can’t keep pace with daily complexity—let alone grow efficiently.

Pro Tip: Every routing problem becomes more expensive when hidden inside spreadsheets. The moment you switch to automated routing optimization, inefficiencies that once felt “normal” vanish—revealing how much time and profit your team can actually save.

The Hidden ROI of Vehicle Routing Optimization

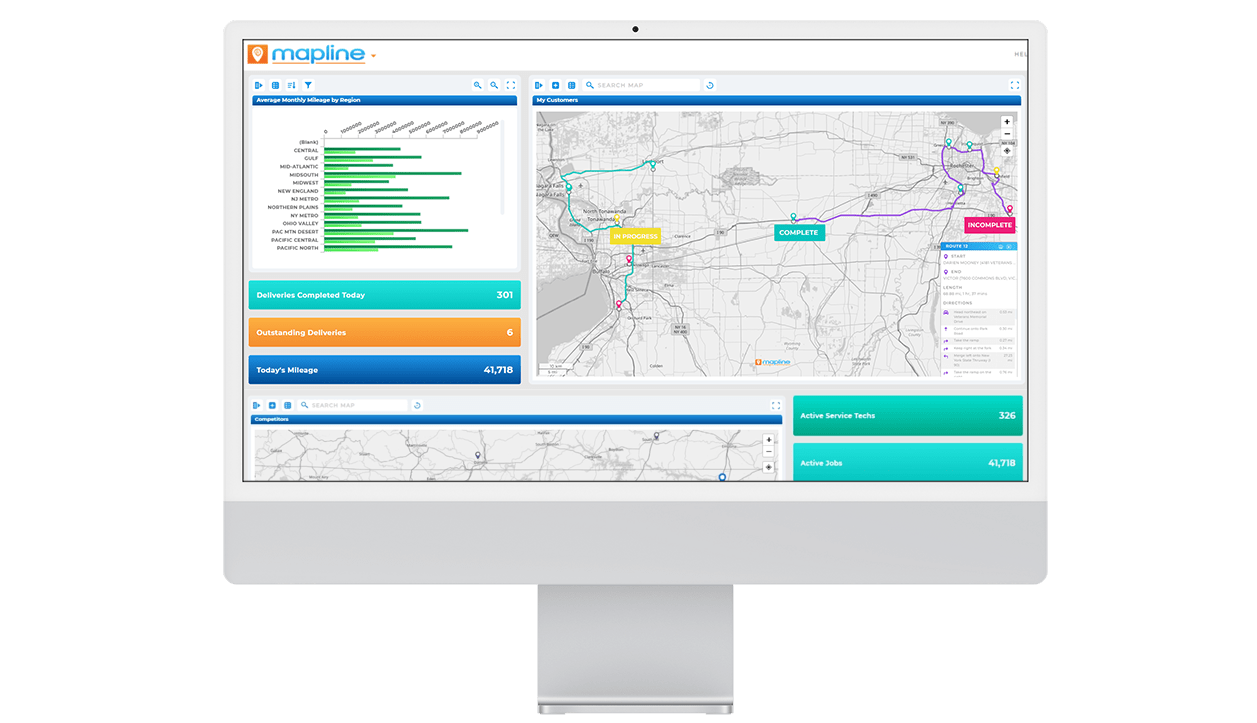

Routing optimization tools reduce cost in ways most teams don’t even track. They shorten drive time, increase completed stops per day, rebalance workloads, and eliminate the “dead miles” that waste fuel and labor. A well-optimized system feels like doubling your fleet capacity without hiring a single new driver. It also improves on-time performance, strengthens customer satisfaction, and gives managers complete visibility into daily operations.

For companies facing tight margins or service-level commitments, routing trucks efficiently is no longer optional—it’s a competitive advantage. The organizations that master routing optimization will consistently outperform those relying on outdated or manual systems.

The Most Common Vehicle Routing Problems (And How to Fix Them)

Every routing team eventually confronts the same set of challenges—too many stops, too many variables, and too little time to calculate the best path forward. These recurring vehicle routing problems create hidden inefficiencies that compound across every driver, route, and region. Fortunately, each challenge has a predictable pattern and an equally predictable solution when the right optimization tools are in place. By understanding the most common routing problems, leaders can identify where their operations are leaking time and profit. Below, we break down the issues that hit most organizations—and the modern strategies that fix them.

Classic Vehicle Routing Problem (VRP)

The traditional vehicle routing problem involves finding the most efficient set of routes for multiple vehicles covering multiple stops. Manual planners often rely on intuition, but with dozens—or hundreds—of stops, the number of possible routes becomes impossible to evaluate by hand. This leads to suboptimal decisions and unnecessary mileage. A vehicle routing system solves this by automating the selection of the most cost-effective routes in seconds.

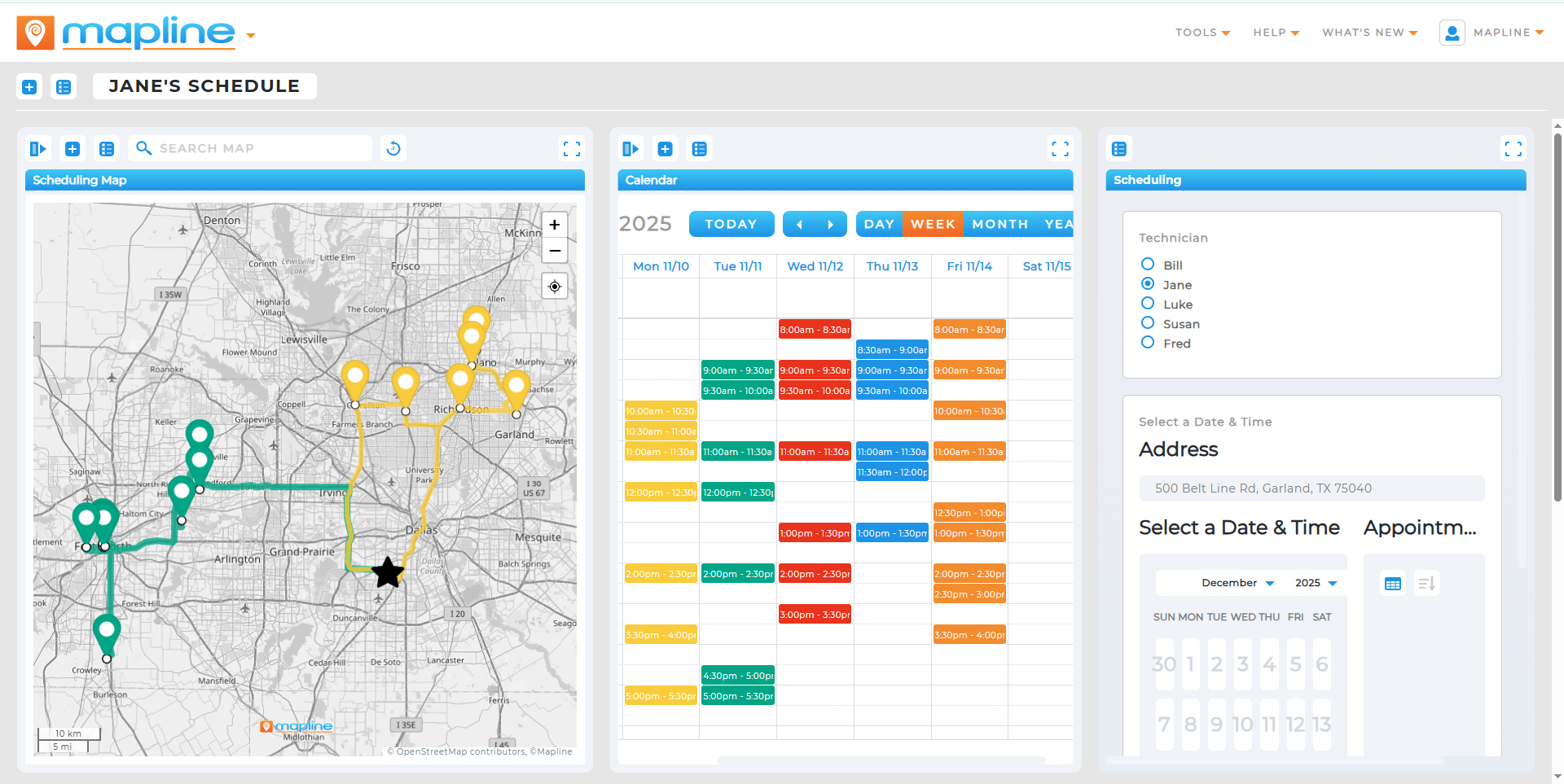

Vehicle Routing Problem With Time Windows

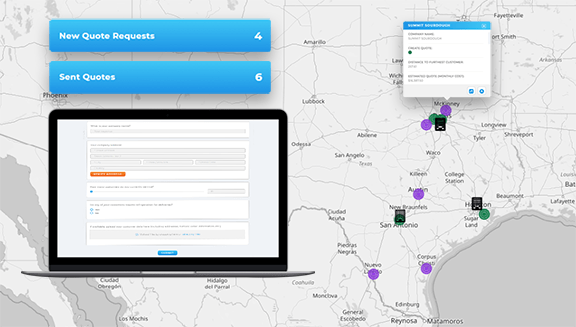

Most teams operate under delivery or service windows—adding a layer of complexity spreadsheets can’t handle. Drivers either arrive too early, too late, or spend excess time waiting. Route optimization ensures every stop falls within the required window while minimizing overall travel time. This not only improves efficiency but also enhances customer satisfaction.

Vehicle Routing Problem With Pickup and Delivery

Pickup-and-delivery operations require matching the right items, loads, or passengers to the right vehicle—and moving them in the correct sequence. A misaligned route can cause capacity violations, long backtracking, and lost hours. Optimized systems ensure pickups and drop-offs occur in the most efficient order while respecting vehicle constraints.

Multi-Depot Vehicle Routing Problem

Companies with multiple hubs, warehouses, or staging areas face extra complexity. Assigning stops to the wrong depot creates wasteful cross-region travel and overloaded locations. Multi-depot optimization assigns each stop to the ideal location and balances workloads across facilities. This reduces operational strain and lowers fleet-wide travel distance.

Salesman Route Planner Problem (Single Route Optimization)

For teams with solo reps or technicians, even a single inefficient route can cost hours. A modern salesman route planner generates the best possible path through all planned stops, accounting for distance, traffic, and priority. It ensures the individual operator completes more visits in less time—boosting productivity without increasing workload.

The routing problem refers to the challenge of determining the most efficient routes for vehicles to complete all required stops. As the number of stops increases, the number of possible route combinations explodes—making manual planning ineffective. This leads to wasted miles, higher fuel costs, and lower productivity.

Small inefficiencies compound across every route and every driver. Extra miles, uneven workloads, overtime, and delays all add up to significant financial loss. Bad routing also damages customer satisfaction and reduces team capacity. The cost is usually far greater than most companies realize.

No. Spreadsheets can store data but can’t compute optimal routing sequences or adjust in real time. They fail when time windows, capacity limits, multiple depots, or last-minute changes come into play. Modern routing systems handle thousands of variables automatically—something no spreadsheet can replicate.

A routing system creates optimized routes instantly while accounting for real-world constraints like traffic, delivery windows, driver availability, and vehicle capacity. It reduces fuel costs, improves service levels, increases daily stop count, and boosts fleet efficiency overall. It’s one of the quickest ways to increase operational profitability.

Any industry with drivers, technicians, deliveries, or service visits benefits. This includes logistics, field service, waste management, utilities, telecommunications, medical delivery, retail distribution, and home services. The more complex the routing, the larger the ROI.

Yes. Modern routing tools recalculate routes instantly when new jobs arrive, cancellations occur, or conditions shift. This keeps operations efficient and responsive—something manual planning cannot achieve.

Customer experience is closely tied to on-time arrival, reliable service windows, and consistent communication. Poor routing creates delays and unpredictable schedules. Optimized routing improves punctuality and helps teams meet commitments consistently.