High-volume logistics operations move fast — and when thousands of deliveries, pickups, or service visits happen each day, teams need visibility that goes far beyond static charts or spreadsheets. Maps combined with dynamic dashboards create a real-time command center that helps logistics teams understand where vehicles are, how routes are progressing, and where delays are emerging. This combination turns raw data into visual, immediate insight, allowing dispatchers, managers, and field teams to respond quickly and confidently. Maps + dashboards aren’t just a helpful add-on — they’re becoming the new standard for logistics visibility at scale.

Why High-Volume Logistics Can’t Rely on Traditional Dashboards

Standard dashboards offer valuable reporting, but lack the geographic awareness required for fast, accurate logistics decision-making. Without a spatial view, teams miss contextual clues like clustered delays, inefficient routes, risky coverage gaps, or traffic-driven slowdowns. High-volume operations need dashboards that combine geographic intelligence with metric-driven insight, giving teams a full picture of fleet performance. In fast-moving environments, spatial visibility is no longer optional — it’s essential.

Pro Tip: Pair map-based dashboards with automated alerts. When KPIs fall below thresholds or delivery windows are at risk, alerts help teams respond before customers feel the impact.

Charts Alone Can’t Show Route Health

Traditional charts can summarize performance but can’t reveal whether issues are isolated or regional, or whether delays share a geographic pattern. Maps show exactly where problems occur and help teams understand their root causes. This spatial context enables more accurate decisions and faster issue resolution than charts alone provide.

Static Dashboards Miss Real-Time Shifts

High-volume logistics operations change minute by minute. Static charts or once-a-day refresh cycles can’t show evolving traffic conditions, late-running vehicles, or canceled stops. Maps with real-time layers keep dispatchers closely aligned with what’s happening on the ground. When the data is live, teams can act immediately instead of reacting hours later.

Without Spatial Insight, Bottlenecks Go Unnoticed

Delays aren’t always caused by driver behavior or poor planning — often they’re tied to geography, weather, or regional demand spikes. Without maps, these patterns stay hidden. When maps are integrated into dashboards, bottlenecks reveal themselves at a glance. This clarity prevents recurring issues that drain performance day after day.

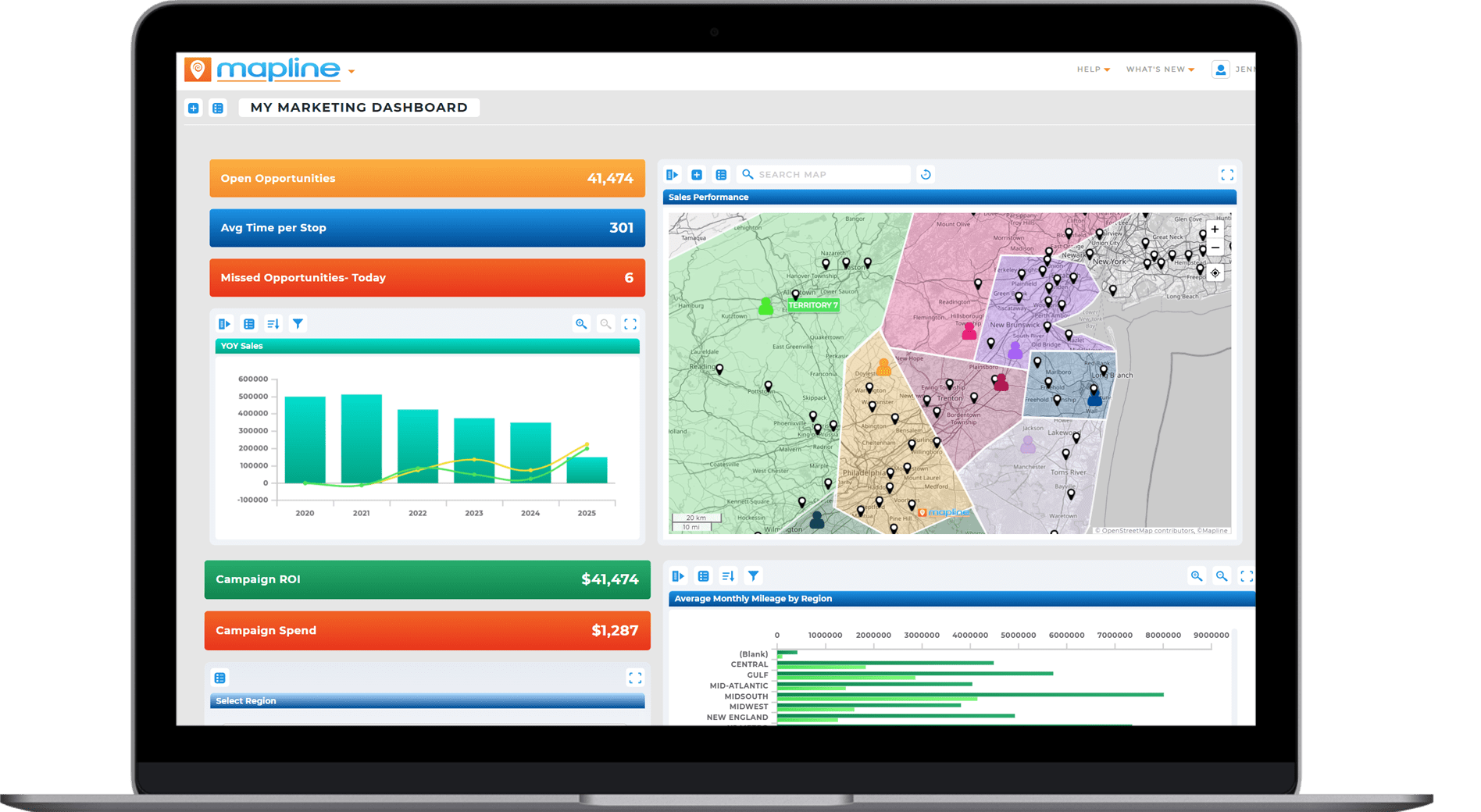

How Maps + Dashboards Deliver Complete Fleet Visibility

Combining spatial intelligence with dynamic KPIs gives logistics teams a unified command center for monitoring and optimizing their fleet. Maps keep teams grounded in real-world context, while dashboards surface the metrics that drive decision-making. Together, they provide a full operational picture that supports smarter routing, better customer communication, and more predictable daily outcomes.

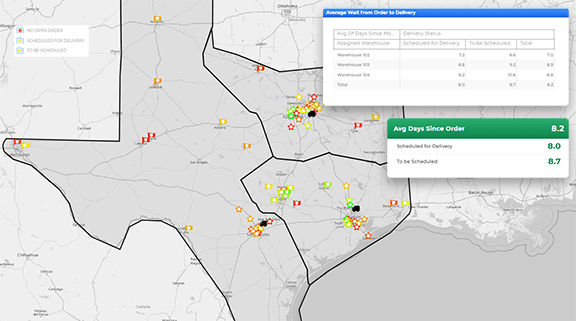

Track Vehicles and Jobs Live on the Map

Live tracking layers let teams watch vehicles progress in real time, showing which routes are on pace, which are falling behind, and where drivers may need support. This visibility helps dispatchers respond instantly to developing issues such as stalled progress, unexpected detours, or urgent new jobs. The map becomes a live pulse of the entire operation.

Monitor Delivery Windows With Visual Indicators

Delivery window KPIs paired with geographic context help teams see which stops are trending late, which regions are on schedule, and where there’s risk of missed commitments. Visual indicators make time-sensitive tasks easy to prioritize. When timing is tight, maps highlight where intervention is needed immediately.

See Route Progress and Deviation in Real Time

Maps show not only where vehicles are, but how closely they’re following the planned route. If a driver takes a detour, encounters congestion, or deviates from the expected path, dispatchers can spot it instantly. This helps teams keep routes efficient, reduce mileage, and stay proactive when issues arise on the road.

Identify and Resolve Live Exceptions Faster

Exceptions — missed stops, delays, cancellations, or urgent add-on jobs — are easier to manage when teams can see them visually. Maps help identify clusters of exceptions or regions trending behind schedule. Dashboards then show the metrics behind those issues. Together, they help teams address problems before they escalate.

Why This Approach Sets the New Standard for Logistics Visibility

As logistics operations scale, complexity grows with every new route, region, or vehicle. Maps + dashboards reduce that complexity by simplifying the flow of information and centralizing real-time insight. Whether managing a handful of vehicles or hundreds, this approach aligns dispatchers, drivers, and managers around a shared, always-updated source of truth. The more complex the operation, the more crucial it becomes to have a visual system that supports fast, accurate decision-making.

Unified Visibility Replaces Fragmented Tools

Instead of switching between mapping apps, spreadsheets, and BI dashboards, teams operate from a single, cohesive platform. This reduces error, simplifies workflow, and shortens response time. When everyone uses the same interface, communication improves across the entire organization.

Spatial Insight Makes Performance Trends Obvious

Maps highlight patterns that would otherwise require hours of analysis to uncover. Geographic visualization exposes systemic issues like overloaded regions, inefficient territory designs, or recurring traffic hotspots. Clear patterns lead to smarter long-term planning and ongoing operational improvement.

Faster Decisions Lead to More Reliable Operations

With real-time visibility, teams make decisions in seconds rather than minutes or hours. Faster responses prevent delays from snowballing and protect on-time performance across the entire fleet. In high-volume logistics, speed is everything — and spatial dashboards deliver the speed modern teams need to stay competitive.

Because maps provide context while dashboards show performance — together they create full operational visibility.

Maps reveal early where delays cluster, while KPIs show how serious the risk is.

Yes — real-time map layers show exactly where drivers differ from the plan.

Absolutely. Maps + dashboards scale easily across hundreds of vehicles or thousands of daily jobs

No — field service, sales, construction, and telecom teams benefit from spatial visibility too.